Color coated aluminum coil features excellent corrosion resistance, great durability, and light weight. It is widely used in public buildings, power plants, steel mills, chemical industries, and other industries. As a metal products supplier, we have prepainted aluminum coil with different aluminum alloys as the base metal. And the popular coating is PE and PVDF. The thickness available is from 0.2 mm to 2.0 mm and the max width is 1,500 mm. More than that, you can choose different colors and patterns according to your needs and preference.

Color Coated Aluminum Coil Specifications

| Item | Color Coated Aluminum Coil |

| Thickness | 0.12mm -2.0mm |

| Width | 600mm – 1500mm |

| Length | According to customers’ request |

| Coil Weight | 2.5 – 3 Tons or Customized |

| Material | 1000 series, 3000 series, 5000 series, etc. |

| Surface Treatment Process | Polishing, mirror finish, lamination, etc. |

| Processing services | Fixed-length cutting, longitudinal cutting, embossing, profiling, etc. |

| Colors | As per RAL Color or Customer Samples |

| Coatings | PE, PVDF |

| Certificates | ISO 9001, SGS, CE, BV |

| Package | Standard Export Package |

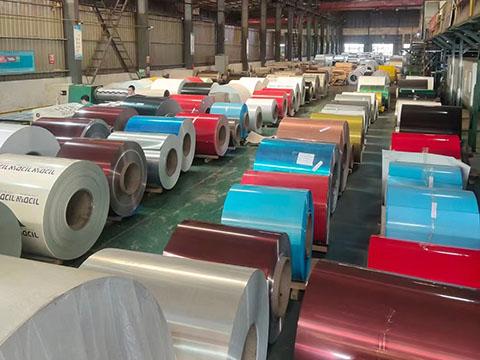

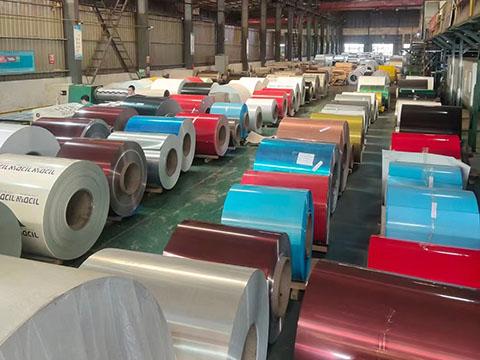

Color Coated Aluminum Coil

Pre-painted Aluminum Coils

We are able to process color coated aluminum coil into the following products:

- Color Coated Aluminum Sheet: with customized cutting equipment, we can accurately cut to the required size with small error.

- Color Coated Aluminum Strip: with slitting equipment, we can cut color coated aluminum strip width 150mm-600mm, which can be customized.

- Color Coated Patterned Aluminum Coil: the patterns that can be processed include willow leaf pattern, pointer, jewel, orange peel pattern or customized.

- Corrugated Aluminum Sheet: Hundreds of press equipment, capable of producing various types of corrugated sheet (aluminum), contact us for corrugated sheet types.

Uses of Color Coated Aluminum Coil

It is widely used in aluminum-plastic panels, buildings, aluminum shutters, composite panels, ceilings, cans, and electronic products.

Construction and decoration: such as roofing panels, aluminum-plastic composite panels, interior aluminum panels, shutter doors, garage doors, ceilings, curtain walls, wall claddings, steel structures, elevators, etc.

Electronic products and household appliances: electrical shells, computer panels, lighting, solar reflectors, water heater, water tank shells;

Traffic signs and automobiles: traffic signs, vehicles interior panel, ship decoration, advertising display boards, luggage;

Furniture: metal furniture, kitchen cabinets, various countertops, partitions, pipeline insulation, etc.

Features of Color Coated Aluminum Coil

High Durability

As we know, color-coated aluminum coil uses aluminum as the substrate. The aluminum itself has strong corrosion resistance. The aluminum molecules combine with oxygen to form an aluminum oxide film, which covers the surface of the aluminum. It can prevent the aluminum from further oxidizing. Plus with the paint, generally PVDF or PE paint, the color coated aluminum is very durable to use.

Light Weight

The density of aluminum alloy is 2.73 kg/m3, which is one-third of that of steel. So it is light in weight, which greatly reduces the load on the support structure. Therefore, the color coated aluminum is widely used in airports, stations, stadiums, and other large-span construction fields.

Color Aluminum Coil

Colored Aluminum Coils

High Strength

Due to the addition of metal components such as magnesium and manganese, the strength, and rigidity of aluminum alloy are greatly enhanced. And its load-bearing performance is improved. The paint will not influence the strength. So the color coated aluminum also features high strength and good rigidity.

Good Plasticity

Color coated aluminum is easy to process and it can be bent into various roof shapes to meet customers’ needs. Different climates, wind pressure, temperature, humidity, and other factors will not cause bending, deformation, expansion, etc.

Great Decorative Effect

Color coated aluminum coils are available in different colors and custom patterns, such as wood grain and stone grain. The beautiful appearance can meet the different needs of architectural style and design requirements.

Excellent Weather Resistance

The paint aluminum coils are made by coating and baking at high temperatures. So it has high gloss retention and good color stability. The polyester-painted aluminum coil is guaranteed for 10 years, and the PVDF painted aluminum coil is guaranteed for more than 20 years.

Color Aluminum Coil at Factory

Painted Aluminum Coils in Stock

Types of Colored Aluminum Sheet

According to the coatings, there are PE-coated aluminum coils and PVDF-coated aluminum coils.

PE-coated aluminum coil

The polyester (PE) coating can firmly attach to the aluminum surface through repeatedly baking and coating. It is a kind of anti-UV ultraviolet coating. Also, it has rich colors with good gloss and smoothness. The coating can protect the base metal from ultraviolet radiation, wind, rain, frost and snow. Especially, it is suitable for interior decoration and advertising boards.

PVDF Painted Aluminum Coil

PVDF coating has excellent abrasion resistance and corrosion resistance. It also has superior weather and UV resistance, especially in harsh climates and environments. Besides, it will maintain its color and luster after 20 years outdoors. Therefore, it is suitable for public buildings, indoor and outdoor decorations, commercial uses, exhibition advertisements, etc.

In addition, our color coated aluminum plates are available in a variety of aluminum grades, such as: 1060 series, 3003/3004 series, 5025 series.

Conclusion

Color-coated aluminum coil has rich colors and patterns. And you can choose matte or glossy surface, smooth or embossed finishes. So it is versatile in residential, commercial, and public buildings. we have both pre-painted aluminum sheets and coils for sale. We also offer value-added services, such as cutting, slitting, profiling, etc. Welcome to contact us for more details.

簡(jiǎn)體中文

簡(jiǎn)體中文